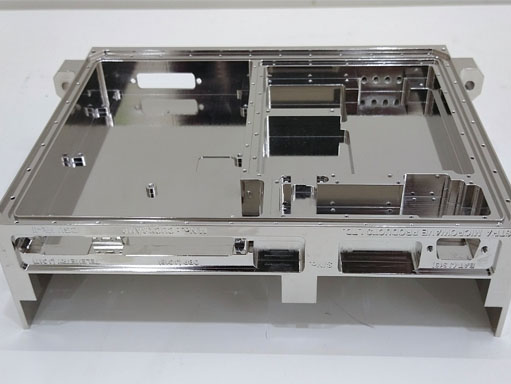

| Bright Nickel Plating (QQ–N–290A)

Nickel can be deposited soft or hard-dull or bright, depending on process used and conditions employed in plating. Thus, hardness can range from 150–500 Vickers. Can be similar to stainless steel in color, or can be dull gray or light gray (almost white) color. Corrosion resistance is a function of thickness.

- Class 1A: For corrosion protection

- Grade A: .0016” Min. thickness

- Grade B: .0012” Min. thickness

- Grade C: .0010” Min. thickness

- Grade D: .0008” Min. thickness

- Grade E: .0006” Min. thickness

- Grade F: .0004” Min. thickness

- Grade G: .0002” Min. thickness

- Class 2: For engineering applications

Electroless Nickel plating, Nickel is generally used as a semi-bright white corrosion resistant finish. Electroless nickel plates with unusually uniform dimensional build up on parts so that you don’t get thick regions at outside corners and thin regions at inside corners and in cavities. Also, E-Nickel is hard and offers good wear resistance. The corrosion resistance improves with increasing phosphorous content. We offer both mid-phosphorus and high-phosphorus E-Nickel solutions. E-Nickel (Plating is) plates very well to many types of aluminum and therefore serves as an excellent base for precious metals, which generally don’t adhere well to aluminum. Mil Spec C–26074